What Is The Regular Price To Repair Both The Front And Back Glass Of A Phone

Glass is a non-crystalline, oft transparent amorphous solid, that has widespread practical, technological, and decorative use in, for instance, window panes, tableware, and eyes. Glass is virtually often formed by rapid cooling (quenching) of the molten form; some glasses such as volcanic glass are naturally occurring. The most familiar, and historically the oldest, types of manufactured drinking glass are "silicate glasses" based on the chemical chemical compound silica (silicon dioxide, or quartz), the primary constituent of sand. Soda-lime glass, containing effectually seventy% silica, accounts for around ninety% of manufactured glass. The term glass, in popular usage, is ofttimes used to refer only to this type of material, although silica-free glasses often take desirable properties for applications in mod communications technology. Some objects, such as drinking glasses and eyeglasses, are so commonly made of silicate-based drinking glass that they are simply called by the name of the material.

Although breakable, buried silicate glass will survive for very long periods if not disturbed, and many examples of glass fragments exist from early on glass-making cultures. Archaeological show suggests glass-making dates back to at to the lowest degree 3,600 BC in Mesopotamia, Egypt, or Syria. The earliest known glass objects were beads, maybe created accidentally during metalworking or the production of faience. Due to its ease of formability into whatsoever shape, glass has been traditionally used for vessels, such every bit bowls, vases, bottles, jars and drinking glasses. In its almost solid forms, it has also been used for paperweights and marbles. Glass tin can be coloured by adding metal salts or painted and printed every bit enamelled glass. The refractive, reflective and manual properties of drinking glass make glass suitable for manufacturing optical lenses, prisms, and optoelectronics materials. Extruded glass fibres accept awarding every bit optical fibres in communications networks, thermal insulating fabric when matted equally drinking glass wool so as to trap air, or in glass-fibre reinforced plastic (fibreglass).

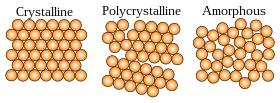

Microscopic structure

The amorphous structure of glassy silica (SiOtwo) in ii dimensions. No long-range order is present, although there is local ordering with respect to the tetrahedral arrangement of oxygen (O) atoms around the silicon (Si) atoms.

Microscopically, a unmarried crystal has atoms in a near-perfect periodic organisation; a polycrystal is equanimous of many microscopic crystals; and an amorphous solid such as glass has no periodic system even microscopically.

The standard definition of a glass (or vitreous solid) is a solid formed by rapid cook quenching.[one] [ii] [3] [four] However, the term "drinking glass" is often defined in a broader sense, to describe any non-crystalline (baggy) solid that exhibits a glass transition when heated towards the liquid country.[4] [v]

Glass is an amorphous solid. Although the atomic-scale structure of drinking glass shares characteristics of the construction of a supercooled liquid, glass exhibits all the mechanical properties of a solid.[half dozen] [7] [8] As in other baggy solids, the diminutive structure of a glass lacks the long-range periodicity observed in crystalline solids. Due to chemical bonding constraints, glasses do possess a loftier degree of short-range guild with respect to local diminutive polyhedra.[9] The notion that drinking glass flows to an appreciable extent over extended periods of time is not supported by empirical research or theoretical analysis (see viscosity in solids). Laboratory measurements of room temperature glass menses do testify a motion consistent with a fabric viscosity on the club of ten17–ten18 Pa due south.[5] [10]

Germination from a supercooled liquid

Unsolved problem in physics :

What is the nature of the transition between a fluid or regular solid and a glassy phase? "The deepest and most interesting unsolved problem in solid state theory is probably the theory of the nature of drinking glass and the glass transition." —P.Due west. Anderson[11]

For melt quenching, if the cooling is sufficiently rapid (relative to the characteristic crystallization time) and then crystallization is prevented and instead the disordered atomic configuration of the supercooled liquid is frozen into the solid land at Tg. The tendency for a material to grade a glass while quenched is chosen glass-forming ability. This ability can be predicted past the rigidity theory.[12] Generally, a glass exists in a structurally metastable state with respect to its crystalline class, although in sure circumstances, for instance in atactic polymers, there is no crystalline analogue of the baggy stage.[13]

Drinking glass is sometimes considered to exist a liquid due to its lack of a first-order phase transition[seven] [14] where sure thermodynamic variables such as volume, entropy and enthalpy are discontinuous through the glass transition range. The glass transition may be described equally coordinating to a 2nd-order stage transition where the intensive thermodynamic variables such as the thermal expansivity and heat capacity are discontinuous, withal this is incorrect.[two] The equilibrium theory of phase transformations do not concur for glass, and hence the glass transition cannot be classed as ane of the classical equilibrium phase transformations in solids.[iv] [v] Furthermore, it does not describe the temperature dependence of Tg upon heating rate, as found in differential scanning calorimetry.

Occurrence in nature

Drinking glass tin form naturally from volcanic magma. Obsidian is a mutual volcanic drinking glass with high silica (SiO2) content formed when felsic lava extruded from a volcano cools rapidly.[xv] Impactite is a form of drinking glass formed by the touch of a meteorite, where Moldavite (found in cardinal and eastern Europe), and Libyan desert glass (found in areas in the eastern Sahara, the deserts of eastern Libya and western Arab republic of egypt) are notable examples.[16] Vitrification of quartz can also occur when lightning strikes sand, forming hollow, branching rootlike structures called fulgurites.[17] Trinitite is a burnished residue formed from the desert floor sand at the Trinity nuclear bomb test site.[18] Edeowie glass, found in Southward Australia, is proposed to originate from Pleistocene grassland fires, lightning strikes, or hypervelocity impact past one or several asteroids or comets.[19]

History

Naturally occurring obsidian drinking glass was used past Stone Age societies as it fractures along very precipitous edges, making information technology ideal for cutting tools and weapons.[20] [21] Glassmaking dates back at least 6000 years, long before humans had discovered how to smelt iron.[twenty] Archaeological evidence suggests that the first true synthetic glass was made in Lebanon and the coastal north Syria, Mesopotamia or ancient Egypt.[22] [23] The earliest known glass objects, of the mid-third millennium BC, were beads, perhaps initially created as accidental by-products of metalworking (slags) or during the production of faience, a pre-drinking glass vitreous material fabricated past a process like to glazing.[24] Early glass was rarely transparent and often contained impurities and imperfections,[twenty] and is technically faience rather than true drinking glass, which did non announced until the 15th century BC.[25] Notwithstanding, ruddy-orange glass chaplet excavated from the Indus Valley Civilisation dated earlier 1700 BC (maybe as early as 1900 BC) predate sustained glass production, which appeared around 1600 BC in Mesopotamia and 1500 BC in Arab republic of egypt.[26] [27] During the Tardily Bronze Historic period in that location was a rapid growth in glassmaking technology in Egypt and Western Asia.[22] Archaeological finds from this menses include coloured glass ingots, vessels, and beads.[22] [28] Much early glass production relied on grinding techniques borrowed from stoneworking, such every bit grinding and carving glass in a cold state.[29]

The term glass developed in the tardily Roman Empire. It was in the Roman glassmaking centre at Trier (located in current-24-hour interval Federal republic of germany) that the late-Latin term glesum originated, probably from a Germanic word for a transparent, lustrous substance.[30] Glass objects have been recovered across the Roman Empire [31] in domestic, funerary,[32] and industrial contexts,[33] likewise as trade items in marketplaces in distant provinces.[34] [35] Examples of Roman drinking glass have been found outside of the former Roman Empire in China,[36] the Baltics, the Centre Due east, and India.[37] The Romans perfected cameo glass, produced by etching and carving through fused layers of unlike colours to produce a design in relief on the glass object.[38]

Windows in the choir of the Basilica of Saint Denis, i of the primeval uses of extensive areas of glass (early 13th-century architecture with restored glass of the 19th century)

In postal service-classical West Africa, Republic of benin was a manufacturer of glass and glass beads.[39] Glass was used extensively in Europe during the Middle Ages. Anglo-Saxon glass has been plant across England during archaeological excavations of both settlement and cemetery sites.[xl] From the 10th century onwards, glass was employed in stained glass windows of churches and cathedrals, with famous examples at Chartres Cathedral and the Basilica of Saint Denis. By the 14th century, architects were designing buildings with walls of stained drinking glass such as Sainte-Chapelle, Paris, (1203–1248) and the Due east finish of Gloucester Cathedral. With the change in architectural manner during the Renaissance period in Europe, the use of large stained glass windows became much less prevalent,[41] although stained glass had a major revival with Gothic Revival compages in the 19th century.[42]

During the 13th century, the island of Murano, Venice, became a centre for glass making, building on medieval techniques to produce colourful ornamental pieces in big quantities.[38] Murano drinking glass makers developed the exceptionally clear colourless drinking glass cristallo, so called for its resemblance to natural crystal, which was extensively used for windows, mirrors, ships' lanterns, and lenses.[twenty] In the 13th, 14th, and 15th centuries, enamelling and gilding on glass vessels was perfected in Egypt and Syrian arab republic.[43] Towards the end of the 17th century, Bohemia became an important region for glass production, remaining then until the start of the 20th century. By the 17th century, glass in the Venetian tradition was also being produced in England. In almost 1675, George Ravenscroft invented lead crystal drinking glass, with cut glass condign stylish in the 18th century.[38] Ornamental glass objects became an important art medium during the Art Nouveau menses in the late 19th century.[38]

Throughout the 20th century, new mass production techniques led to widespread availability of glass in much larger amounts, making it practical as a edifice textile and enabling new applications of glass.[44] In the 1920s a mould-etch process was developed, in which art was etched straight into the mould, so that each cast piece emerged from the mould with the image already on the surface of the drinking glass. This reduced manufacturing costs and, combined with a wider use of coloured glass, led to cheap glassware in the 1930s, which after became known as Depression glass.[45] In the 1950s, Pilkington Bros., England, adult the float drinking glass process, producing high-quality distortion-free flat sheets of drinking glass by floating on molten tin can.[20] Modern multi-story buildings are ofttimes constructed with curtain walls made most entirely of drinking glass.[46] Laminated glass has been widely applied to vehicles for windscreens.[47] Optical glass for spectacles has been used since the Heart Ages.[48] The product of lenses has get increasingly skillful, aiding astronomers[49] likewise as having other awarding in medicine and science.[50] Glass is also employed as the aperture cover in many solar free energy collectors.[51]

In the 21st century, glass manufacturers have developed different brands of chemically strengthened glass for widespread awarding in touchscreens for smartphones, tablet computers, and many other types of information appliances. These include Gorilla glass, developed and manufactured past Corning, AGC Inc.'south Dragontrail and Schott AG'southward Xensation.[52] [53] [54]

Concrete properties

Optical

Glass is in widespread use in optical systems due to its ability to refract, reflect, and transmit light post-obit geometrical eyes. The most common and oldest applications of glass in optics are as lenses, windows, mirrors, and prisms.[55] The key optical backdrop refractive index, dispersion, and transmission, of drinking glass are strongly dependent on chemical composition and, to a lesser caste, its thermal history.[55] Optical glass typically has a refractive index of 1.4 to two.iv, and an Abbe number (which characterises dispersion) of 15 to 100.[55] Refractive index may be modified by loftier-density (refractive index increases) or depression-density (refractive index decreases) additives.[56]

Drinking glass transparency results from the absenteeism of grain boundaries which diffusely besprinkle light in polycrystalline materials.[57] Semi-opacity due to crystallization may be induced in many glasses by maintaining them for a long menstruation at a temperature just insufficient to cause fusion. In this way, the crystalline, devitrified material, known as Réaumur's glass porcelain is produced.[43] [58] Although generally transparent to visible light, glasses may be opaque to other wavelengths of low-cal. While silicate glasses are generally opaque to infrared wavelengths with a transmission cutting-off at 4 μm, heavy-metallic fluoride and chalcogenide spectacles are transparent to infrared wavelengths of upwards to 7 and upwards to 18 μm, respectively.[59] The addition of metallic oxides results in different coloured glasses equally the metallic ions will absorb wavelengths of low-cal corresponding to specific colours.[59]

Other

In the manufacturing process, glasses can be poured, formed, extruded and moulded into forms ranging from flat sheets to highly intricate shapes.[60] The finished product is breakable and will fracture, unless laminated or tempered to enhance immovability.[61] [62] Drinking glass is typically inert, resistant to chemical attack, and can mostly withstand the action of water, making information technology an platonic cloth for the manufacture of containers for foodstuffs and most chemicals.[20] [63] [64] Nevertheless, although commonly highly resistant to chemic assault, drinking glass volition corrode or dissolve under some conditions.[63] [65] The materials that make up a particular glass limerick have an effect on how quickly the drinking glass corrodes. Glasses containing a high proportion of alkali or alkaline earth elements are more susceptible to corrosion than other glass compositions.[66] [67]

The density of glass varies with chemical composition with values ranging from 2.two grams per cubic centimetre (2,200 kg/mthree) for fused silica to 7.ii grams per cubic centimetre (7,200 kg/1000iii) for dense flintstone glass.[68] Drinking glass is stronger than most metals, with a theoretical tensile force for pure, flawless glass estimated at 14 gigapascals (2,000,000 psi) to 35 gigapascals (v,100,000 psi) due to its ability to undergo reversible compression without fracture. However, the presence of scratches, bubbling, and other microscopic flaws lead to a typical range of fourteen megapascals (2,000 psi) to 175 megapascals (25,400 psi) in nigh commercial glasses.[59] Several processes such as toughening can increase the forcefulness of drinking glass.[69] Carefully drawn flawless drinking glass fibres tin can be produced with forcefulness of up to 11.5 gigapascals (1,670,000 psi).[59]

Reputed flow

The observation that former windows are sometimes found to be thicker at the bottom than at the top is oft offered as supporting show for the view that drinking glass flows over a timescale of centuries, the assumption existence that the drinking glass has exhibited the liquid property of flowing from one shape to another.[70] This assumption is incorrect, as once solidified, glass stops flowing. The sags and ripples observed in old glass were already there the 24-hour interval information technology was made; manufacturing processes used in the past produced sheets with imperfect surfaces and not-uniform thickness.[7] (The nearly-perfect bladder glass used today only became widespread in the 1960s.)

Types

Silicate

Quartz sand (silica) is the main raw fabric in commercial glass production

Silicon dioxide (SiOii) is a mutual fundamental constituent of drinking glass. Fused quartz is a drinking glass made from chemically-pure silica.[67] It has very low thermal expansion and excellent resistance to thermal stupor, being able to survive immersion in water while red hot, resists high temperatures (1000–1500 °C) and chemic weathering, and is very difficult. It is also transparent to a wider spectral range than ordinary glass, extending from the visible further into both the UV and IR ranges, and is sometimes used where transparency to these wavelengths is necessary. Fused quartz is used for high-temperature applications such as furnace tubes, lighting tubes, melting crucibles, etc.[71] However, its loftier melting temperature (1723 °C) and viscosity arrive difficult to piece of work with. Therefore, usually, other substances (fluxes) are added to lower the melting temperature and simplify glass processing.[72]

Soda-lime

Sodium carbonate (Na2CO3, "soda") is a common additive and acts to lower the drinking glass-transition temperature. Still, sodium silicate is h2o soluble, and then lime (CaO, calcium oxide, more often than not obtained from limestone), some magnesium oxide (MgO) and aluminium oxide (Al2O3) are other common components added to improve chemical durability. Soda-lime spectacles (Na2O) + lime (CaO) + magnesia (MgO) + alumina (Al2Othree) business relationship for over 75% of manufactured glass, containing about 70 to 74% silica by weight.[67] [73] Soda-lime-silicate glass is transparent, easily formed, and well-nigh suitable for window glass and tableware.[74] Nonetheless, it has a loftier thermal expansion and poor resistance to rut.[74] Soda-lime glass is typically used for windows, bottles, light bulbs, and jars.[72]

Borosilicate

Borosilicate spectacles (due east.g. Pyrex, Duran) typically contain 5–thirteen% boron trioxide (BtwoOthree).[72] Borosilicate spectacles have fairly low coefficients of thermal expansion (7740 Pyrex CTE is iii.25×10 −half dozen /°C[75] equally compared to nigh 9×x −6 /°C for a typical soda-lime glass[76]). They are, therefore, less subject to stress caused by thermal expansion and thus less vulnerable to smashing from thermal stupor. They are commonly used for eastward.m. labware, household cookware, and sealed beam car head lamps.[72]

Pb

The addition of lead(2) oxide into silicate glass lowers melting point and viscosity of the melt.[77] The high density of lead glass (silica + atomic number 82 oxide (PbO) + potassium oxide (K2O) + soda (NatwoO) + zinc oxide (ZnO) + alumina) results in a high electron density, and hence high refractive index, making the look of glassware more brilliant and causing noticeably more than specular reflection and increased optical dispersion.[67] [78] Lead glass has a high elasticity, making the glassware more than workable and giving rise to a clear "band" sound when struck. All the same, atomic number 82 drinking glass cannot withstand high temperatures well.[71] Lead oxide also facilitates solubility of other metal oxides and is used in colored drinking glass. The viscosity subtract of lead glass melt is very significant (roughly 100 times in comparison with soda glass); this allows easier removal of bubbles and working at lower temperatures, hence its frequent use as an additive in vitreous enamels and glass solders. The loftier ionic radius of the Lead2+ ion renders information technology highly immobile and hinders the movement of other ions; lead glasses therefore take high electrical resistance, about 2 orders of magnitude higher than soda-lime drinking glass (108.5 vs 106.5 Ω⋅cm, DC at 250 °C).[79]

Aluminosilicate

Aluminosilicate glass typically contains 5-10% alumina (Al2O3). Aluminosilicate glass tends to be more difficult to melt and shape compared to borosilicate compositions, but has first-class thermal resistance and durability.[72] Aluminosilicate glass is extensively used for fiberglass,[fourscore] used for making drinking glass-reinforced plastics (boats, fishing rods, etc.), top-of-stove cookware, and halogen bulb glass.[71] [72]

Other oxide additives

The add-on of barium as well increases the refractive index. Thorium oxide gives glass a high refractive index and low dispersion and was formerly used in producing high-quality lenses, but due to its radioactivity has been replaced by lanthanum oxide in modernistic eyeglasses.[81] Iron can be incorporated into glass to absorb infrared radiation, for example in rut-arresting filters for flick projectors, while cerium(Four) oxide can be used for glass that absorbs ultraviolet wavelengths.[82] Fluorine lowers the dielectric abiding of glass. Fluorine is highly electronegative and lowers the polarizability of the material. Fluoride silicate spectacles are used in industry of integrated circuits every bit an insulator.[83]

Glass-ceramics

Glass-ceramic materials comprise both not-crystalline drinking glass and crystalline ceramic phases. They are formed by controlled nucleation and partial crystallisation of a base of operations glass by oestrus treatment.[84] Crystalline grains are often embedded within a non-crystalline intergranular phase of grain boundaries. Glass-ceramics showroom advantageous thermal, chemical, biological, and dielectric backdrop every bit compared to metals or organic polymers.[84]

The most commercially important belongings of glass-ceramics is their imperviousness to thermal shock. Thus, glass-ceramics have become extremely useful for countertop cooking and industrial processes. The negative thermal expansion coefficient (CTE) of the crystalline ceramic stage tin be counterbalanced with the positive CTE of the burnished phase. At a certain point (~seventy% crystalline) the drinking glass-ceramic has a cyberspace CTE near nix. This type of glass-ceramic exhibits first-class mechanical properties and can sustain repeated and quick temperature changes up to 1000 °C.[85] [84]

Fibreglass

Fibreglass (besides called glass fibre reinforced plastic, GRP) is a composite material made past reinforcing a plastic resin with drinking glass fibres. It is made by melting glass and stretching the glass into fibres. These fibres are woven together into a fabric and left to set in a plastic resin.[86] [87] [88] Fibreglass has the properties of existence lightweight and corrosion resistant, and is a good insulator enabling its use as edifice insulation material and for electronic housing for consumer products. Fibreglass was originally used in the U.k. and United states during Earth War II to manufacture radomes. Uses of fibreglass include edifice and construction materials, boat hulls, automobile body parts, and aerospace composite materials.[89] [86] [88]

Glass-fibre wool is an excellent thermal and sound insulation fabric, commonly used in buildings (east.g. attic and crenel wall insulation), and plumbing (eastward.g. piping insulation), and soundproofing.[89] It is produced by forcing molten glass through a fine mesh past centripetal strength, and breaking the extruded drinking glass fibres into short lengths using a stream of high-velocity air. The fibres are bonded with an adhesive spray and the resulting wool mat is cut and packed in rolls or panels.[59]

Non-silicate

Besides common silica-based glasses many other inorganic and organic materials may also form glasses, including metals, aluminates, phosphates, borates, chalcogenides, fluorides, germanates (glasses based on GeO2), tellurites (glasses based on TeO2), antimonates (glasses based on SbiiO3), arsenates (spectacles based on AsiiOiii), titanates (glasses based on TiO2), tantalates (glasses based on Ta2O5), nitrates, carbonates, plastics, acrylic, and many other substances.[5] Some of these glasses (east.g. Germanium dioxide (GeO2, Germania), in many respects a structural counterpart of silica, fluoride, aluminate, phosphate, borate, and chalcogenide glasses) accept physico-chemic properties useful for their awarding in fibre-optic waveguides in communication networks and other specialized technological applications.[91] [92]

Silica-free glasses may frequently have poor glass forming tendencies. Novel techniques, including containerless processing past aerodynamic levitation (cooling the melt whilst it floats on a gas stream) or splat quenching (pressing the cook between two metal anvils or rollers), may be used increase cooling rate, or reduce crystal nucleation triggers.[93] [94] [95]

Amorphous metals

Samples of amorphous metal, with millimeter scale

In the past, small batches of amorphous metals with high expanse configurations (ribbons, wires, films, etc.) take been produced through the implementation of extremely rapid rates of cooling. Baggy metallic wires have been produced past sputtering molten metal onto a spinning metal disk. More recently a number of alloys have been produced in layers with thickness exceeding 1 millimeter. These are known equally bulk metallic glasses (BMG). Liquidmetal Technologies sell a number of zirconium-based BMGs. Batches of amorphous steel have also been produced that demonstrate mechanical properties far exceeding those found in conventional steel alloys.[96] [97] [98]

Experimental evidence indicates that the system Al-Fe-Si may undergo a beginning-club transition to an amorphous form (dubbed "q-glass") on rapid cooling from the melt. Transmission electron microscopy (TEM) images indicate that q-glass nucleates from the cook as discrete particles with a uniform spherical growth in all directions. While x-ray diffraction reveals the isotropic nature of q-glass, a nucleation barrier exists implying an interfacial discontinuity (or internal surface) between the drinking glass and melt phases.[99] [100]

Polymers

Important polymer glasses include baggy and glassy pharmaceutical compounds. These are useful because the solubility of the chemical compound is greatly increased when it is amorphous compared to the same crystalline composition. Many emerging pharmaceuticals are practically insoluble in their crystalline forms.[101] Many polymer thermoplastics familiar from everyday apply are spectacles. For many applications, similar glass bottles or eyewear, polymer glasses (acrylic drinking glass, polycarbonate or polyethylene terephthalate) are a lighter culling to traditional glass.[102]

Molecular liquids and molten salts

Molecular liquids, electrolytes, molten salts, and aqueous solutions are mixtures of unlike molecules or ions that practice not grade a covalent network just interact just through weak van der Waals forces or through transient hydrogen bonds. In a mixture of three or more ionic species of different size and shape, crystallization can be so difficult that the liquid tin can easily exist supercooled into a glass.[103] [104] Examples include LiCl:RH2O (a solution of lithium chloride common salt and h2o molecules) in the composition range 4<R<8.[105] saccharide glass,[106] or Ca0.4K0.6(NOthree)i.4.[107] Drinking glass electrolytes in the form of Ba-doped Li-glass and Ba-doped Na-glass have been proposed every bit solutions to problems identified with organic liquid electrolytes used in modernistic lithium-ion battery cells.[108]

Production

Robotized float glass unloading

Following the glass batch preparation and mixing, the raw materials are transported to the furnace. Soda-lime glass for mass production is melted in gas fired units. Smaller scale furnaces for specialty glasses include electrical melters, pot furnaces, and day tanks.[73] Subsequently melting, homogenization and refining (removal of bubbles), the drinking glass is formed. Flat glass for windows and like applications is formed by the float glass procedure, developed between 1953 and 1957 by Sir Alastair Pilkington and Kenneth Bickerstaff of the UK'due south Pilkington Brothers, who created a continuous ribbon of glass using a molten tin bath on which the molten drinking glass flows unhindered under the influence of gravity. The top surface of the glass is subjected to nitrogen under pressure level to obtain a polished finish.[109] Container glass for common bottles and jars is formed by blowing and pressing methods.[110] This glass is oftentimes slightly modified chemically (with more alumina and calcium oxide) for greater water resistance.[111]

Once the desired class is obtained, glass is unremarkably annealed for the removal of stresses and to increase the glass'due south hardness and durability.[112] Surface treatments, coatings or lamination may follow to improve the chemical immovability (glass container coatings, glass container internal treatment), strength (toughened glass, bulletproof drinking glass, windshields[113]), or optical backdrop (insulated glazing, anti-cogitating coating).[114]

New chemical glass compositions or new treatment techniques can be initially investigated in small-scale-calibration laboratory experiments. The raw materials for laboratory-scale glass melts are often different from those used in mass production because the toll cistron has a low priority. In the laboratory more often than not pure chemicals are used. Care must be taken that the raw materials have not reacted with wet or other chemicals in the environment (such equally alkali or element of group i earth metal oxides and hydroxides, or boron oxide), or that the impurities are quantified (loss on ignition).[115] Evaporation losses during glass melting should be considered during the selection of the raw materials, eastward.g., sodium selenite may be preferred over hands evaporating selenium dioxide (SeO2). Also, more readily reacting raw materials may be preferred over relatively inert ones, such equally aluminum hydroxide (Al(OH)3) over alumina (AliiO3). Commonly, the melts are carried out in platinum crucibles to reduce contagion from the crucible cloth. Drinking glass homogeneity is achieved by homogenizing the raw materials mixture (glass batch), by stirring the cook, and by crushing and re-melting the first melt. The obtained glass is normally annealed to prevent breakage during processing.[115] [116]

Colour

Colour in glass may be obtained by addition of homogenously distributed electrically charged ions (or colour centres). While ordinary soda-lime glass appears colourless in thin section, atomic number 26(Two) oxide (FeO) impurities produce a light-green tint in thick sections.[117] Manganese dioxide (MnOtwo), which gives drinking glass a purple colour, may exist added to remove the green tint given by FeO.[118] FeO and chromium(III) oxide (Cr2Oiii) additives are used in the production of green bottles.[117] Iron (Three) oxide, on the other-hand, produces yellow or xanthous-brown glass.[119] Low concentrations (0.025 to 0.i%) of cobalt oxide (CoO) produces rich, deep blue cobalt glass.[120] Chromium is a very powerful colourising agent, yielding dark light-green.[121] Sulphur combined with carbon and atomic number 26 salts produces amber glass ranging from xanthous to almost black.[122] A glass cook tin can also larn an amber colour from a reducing combustion atmosphere.[123] Cadmium sulfide produces purple cerise, and combined with selenium can produce shades of xanthous, orange, and red.[117] [119] The additive Copper(Ii) oxide (CuO) produces a turquoise colour in drinking glass, in contrast to Copper(I) oxide (Cu2O) which gives a deadening brown-ruddy colour.[124]

-

-

Ruby-red glass bottle with yellowish glass overlay

-

Amber-coloured drinking glass

-

Four-color Roman drinking glass bowl, manufactured circa 1st century B.C.

Uses

Architecture and windows

Soda-lime sail glass is typically used every bit transparent glazing textile, typically as windows in external walls of buildings. Float or rolled sheet drinking glass products is cut to size either by scoring and snapping the material, laser cut, water jets, or diamond bladed saw. The glass may be thermally or chemically tempered (strengthened) for safe and bent or curved during heating. Surface coatings may be added for specific functions such as scratch resistance, blocking specific wavelengths of light (e.g. infrared or ultraviolet), clay-repellence (e.grand. self-cleaning drinking glass), or switchable electrochromic coatings.[125]

Structural glazing systems represent one of the most significant architectural innovations of modern times, where glass buildings now oftentimes dominate skylines of many modernistic cities.[126] These systems employ stainless steel fittings countersunk into recesses in the corners of the glass panels allowing strengthened panes to announced unsupported creating a flush exterior.[126] Structural glazing systems have their roots in iron and glass conservatories of the nineteenth century[127]

Tableware

Glass is an essential component of tableware and is typically used for h2o, beer and vino drinking glasses.[50] Wine glasses are typically stemware, i.e. goblets formed from a bowl, stem, and foot. Crystal or Lead crystal drinking glass may be cutting and polished to produce decorative drinking glasses with gleaming facets.[128] [129] Other uses of glass in tableware include decanters, jugs, plates, and bowls.[50]

-

Wine glasses and other glass tableware

-

Dimpled glass beer pint jug

-

-

Packaging

The inert and impermeable nature of glass makes it a stable and widely used textile for food and drink packaging every bit glass bottles and jars. About container glass is soda-lime glass, produced by blowing and pressing techniques. Container drinking glass has a lower magnesium oxide and sodium oxide content than flat drinking glass, and a higher silica, calcium oxide, and aluminum oxide content.[130] Its higher content of h2o-insoluble oxides imparts slightly higher chemical durability against water, which is advantageous for storing beverages and food. Glass packaging is sustainable, readily recycled, reusable and refillable.[131]

For electronics applications, glass can be used as a substrate in the manufacture of integrated passive devices, thin-film bulk audio-visual resonators, and every bit a hermetic sealing material in device packaging,[132] [133] including very thin solely glass based encapsulation of integrated circuits and other semiconductors in loftier manufacturing volumes.[134]

Laboratories

Glass is an important material in scientific laboratories for the manufacture of experimental apparatus because it is relatively cheap, readily formed into required shapes for experiment, easy to keep clean, can withstand heat and common cold handling, is generally not-reactive with many reagents, and its transparency allows for the ascertainment of chemical reactions and processes.[135] [136] Laboratory glassware applications include flasks, petri dishes, test tubes, pipettes, graduated cylinders, glass lined metallic containers for chemical processing, fractionation columns, drinking glass pipes, Schlenk lines, gauges, and thermometers.[137] [135] Although nigh standard laboratory glassware has been mass-produced since the 1920s, scientists still employ skilled glassblowers to manufacture bespoke drinking glass apparatus for their experimental requirements.[138]

-

A Vigreux column in a laboratory setup

-

-

Eyes

Glass is a ubiquitous material in eyes past virtue of its ability to refract, reflect, and transmit light. These and other optical backdrop tin can exist controlled past varying chemic compositions, thermal handling, and manufacturing techniques. The many applications of glass in eyes includes glasses for eyesight correction, imaging optics (e.1000. lenses and mirrors in telescopes, microscopes, and cameras), fibre eyes in telecommunications technology, and integrated optics. Microlenses and gradient-index optics (where the refractive index is non-uniform) find application in e.g. reading optical discs, laser printers, photocopiers, and laser diodes.[55]

Art

Role of German stained glass panel of 1444 with the Visitation; pot metal coloured glass of various colours, including white drinking glass, black vitreous paint, yellow silver stain, and the "olive-green" parts are enamel. The plant patterns in the blood-red sky are formed by scratching abroad black pigment from the red glass before firing. A restored panel with new lead cames.

Drinking glass every bit art dates to to the lowest degree 1300 BC shown as an instance of natural drinking glass found in Tutankhamun'southward pectoral, [139] which also independent vitreous enamel, that is to say, melted coloured glass used on a metal bankroll. Enamelled drinking glass, the ornamentation of glass vessels with coloured drinking glass paints, has existed since 1300 BC,[140] and was prominent in the early 20th century with Art Nouveau glass and that of the House of Fabergé in St. Petersburg, Russia. Both techniques were used in stained glass, which reached its elevation roughly from yard to 1550, before a revival in the 19th century.

The 19th century saw a revival in aboriginal glass-making techniques including cameo drinking glass, accomplished for the first fourth dimension since the Roman Empire, initially mostly for pieces in a neo-classical style. The Art Nouveau movement made bang-up apply of glass, with René Lalique, Émile Gallé, and Daum of Nancy in the kickoff French wave of the motion, producing coloured vases and like pieces, oft in cameo drinking glass or in lustre drinking glass techniques.[141]

Louis Condolement Tiffany in America specialized in stained glass, both secular and religious, in panels and his famous lamps. The early 20th-century saw the large-scale factory product of glass art by firms such as Waterford and Lalique. Small studios may mitt-produce drinking glass artworks. Techniques for producing glass fine art include blowing, kiln-casting, fusing, slumping, pâte de verre, flame-working, hot-sculpting and cold-working. Cold work includes traditional stained glass piece of work and other methods of shaping glass at room temperature. Objects made out of drinking glass include vessels, paperweights, marbles, beads, sculptures and installation fine art.[142]

-

Émile Gallé, Marquetry drinking glass vase with clematis flowers (1890-1900)

-

-

-

A glass sculpture by Dale Chihuly, "The Sun" at the "Gardens of Glass" exhibition in Kew Gardens, London

-

Modern stained glass window

Meet also

- Burn glass

- Flexible drinking glass

- Kimberley points

- Prince Rupert's drop

- Smart glass

References

- ^ ASTM definition of glass from 1945

- ^ a b Zallen, R. (1983). The Physics of Amorphous Solids. New York: John Wiley. pp. 1–32. ISBN978-0-471-01968-eight.

- ^ Cusack, N.Eastward. (1987). The physics of structurally disordered matter: an introduction. Adam Hilger in association with the University of Sussex press. p. thirteen. ISBN978-0-85274-829-9.

- ^ a b c Scholze, Horst (1991). Glass – Nature, Structure, and Backdrop. Springer. pp. 3–five. ISBN978-0-387-97396-8.

- ^ a b c d Elliot, Due south.R. (1984). Physics of Amorphous Materials. Longman group ltd. pp. ane–52. ISBN0-582-44636-8.

- ^ Neumann, Florin. "Glass: Liquid or Solid – Science vs. an Urban Legend". Archived from the original on 9 April 2007. Retrieved viii April 2007.

- ^ a b c Gibbs, Philip. "Is drinking glass liquid or solid?". Archived from the original on 29 March 2007. Retrieved 21 March 2007.

- ^ "Philip Gibbs" Drinking glass Worldwide, (May/June 2007), pp. xiv–18

- ^ Salmon, P.S. (2002). "Order within disorder". Nature Materials. 1 (2): 87–8. doi:10.1038/nmat737. PMID 12618817. S2CID 39062607.

- ^ Vannoni, M.; Sordini, A.; Molesini, Thousand. (2011). "Relaxation time and viscosity of fused silica glass at room temperature". Eur. Phys. J. East. 34 (9): nine–fourteen. doi:ten.1140/epje/i2011-11092-nine. PMID 21947892. S2CID 2246471.

- ^ Anderson, P.W. (1995). "Through the Drinking glass Lightly". Science. 267 (5204): 1615–xvi. doi:x.1126/science.267.5204.1615-e. PMID 17808155. S2CID 28052338.

- ^ Phillips, J.C. (1979). "Topology of covalent not-crystalline solids I: Short-range order in chalcogenide alloys". Journal of Non-Crystalline Solids. 34 (2): 153. Bibcode:1979JNCS...34..153P. doi:10.1016/0022-3093(79)90033-iv.

- ^ Folmer, J.C.Westward.; Franzen, Stefan (2003). "Study of polymer glasses by modulated differential scanning calorimetry in the undergraduate physical chemistry laboratory". Journal of Chemical Pedagogy. 80 (7): 813. Bibcode:2003JChEd..80..813F. doi:10.1021/ed080p813.

- ^ Loy, Jim. "Drinking glass Is A Liquid?". Archived from the original on 14 March 2007. Retrieved 21 March 2007.

- ^ "Obsidian: Igneous Stone – Pictures, Uses, Properties". geology.com.

- ^ "Impactites: Bear on Breccia, Tektites, Moldavites, Shattercones". geology.com.

- ^ Klein, Hermann Joseph (1 January 1881). Land, body of water and sky; or, Wonders of life and nature, tr. from the Germ. [Die Erde und ihr organisches Leben] of H.J. Klein and dr. Thomé, by J. Minshull.

- ^ Giaimo, Cara (June thirty, 2022). "The Long, Weird Half-Life of Trinitite". Atlas Obscura . Retrieved July 8, 2022.

- ^ Roperch, Pierrick; Gattacceca, Jérôme; Valenzuela, Millarca; Devouard, Bertrand; Lorand, Jean-Pierre; Arriagada, Cesar; Rochette, Pierre; Latorre, Claudio; Beck, Pierre (2017). "Surface vitrification acquired past natural fires in Late Pleistocene wetlands of the Atacama Desert". Earth and Planetary Science Messages. 469 (ane July 2022): 15–26. Bibcode:2017E&PSL.469...15R. doi:x.1016/j.epsl.2017.04.009.

- ^ a b c d e f Ward-Harvey, M. (2009). Central Edifice Materials. Universal-Publishers. pp. 83–90. ISBN978-1-59942-954-0.

- ^ "Digs Reveal Stone-Age Weapons Manufacture With Staggering Output". National Geographic News. 13 Apr 2022.

- ^ a b c Julian Henderson (2013). Ancient Drinking glass. Cambridge Academy Printing. pp. 127–157. doi:10.1017/CBO9781139021883.006.

- ^ "Glass Online: The History of Glass". Archived from the original on 24 Oct 2022. Retrieved 29 Oct 2007.

- ^ "All Near Glass | Corning Museum of Glass". world wide web.cmog.org.

- ^ Karklins, Karlis (January 2022). "Simon Kwan -- Early Chinese Faience and Glass Beads and Pendants". BEADS: Journal of the Society of Dewdrop Researchers.

- ^ Kenoyer, J.1000 (2001). "Bead Technologies at Harappa, 3300-1900 BC: A Comparative Summary". S Asian Archæology (PDF). Paris. pp. 157–170.

- ^ McIntosh, Jane (2008). The Ancient Indus Valley: New Perspectives. ABC-CLIO. p. 99. ISBN978-1-57607-907-2.

- ^ "How did Manufactured Glass Develop in the Bronze Age? - DailyHistory.org". dailyhistory.org.

- ^ Wilde, H. "Technologische Innovationen im 2. Jahrtausend v. Chr. Zur Verwendung und Verbreitung neuer Werkstoffe im ostmediterranen Raum". GOF 4, Bd 44, Wiesbaden 2003, 25–26.

- ^ Douglas, R.Due west. (1972). A history of glassmaking. Henley-on-Thames: Thou T Foulis & Co Ltd. p. 5. ISBN978-0-85429-117-v.

- ^ Whitehouse, David (2003). Roman Glass in the Corning Museum of Glass, Volume 3. Hudson Hills. p. 45. ISBN978-0-87290-155-one.

- ^ The Art Journal. Virtue and Company. 1888. p. 365.

- ^ Chocolate-brown, A.Fifty. (November 1921). "The Manufacture of Glass Milk Bottles". The Glass Industry. Ashlee Publishing Company. two (11): 259.

- ^ Aton, Francesca, Perfectly Preserved 2,000-Year-Old Roman Glass Bowl Unearthed in the netherlands, Fine art News, January 25, 2022

- ^ McGreevy, Nora, ii,000-Year-Old Roman Bowl Discovered Intact in the Netherlands, National Geographic, January 28, 2022

- ^ Dien, Albert E. (2007). Vi Dynasties Civilization. Yale Academy Press. p. 290. ISBN978-0-300-07404-8.

- ^ Silberman, Neil Asher; Bauer, Alexander A. (2012). The Oxford Companion to Archæology. Oxford University Printing. p. 29. ISBN978-0-xix-973578-5.

- ^ a b c d "glass | Definition, Composition, & Facts". Encyclopedia Britannica.

- ^ Oliver, Roland, and Fagan, Brian One thousand. Africa in the Iron Age, c500 B.C. to A.D. 1400. New York: Cambridge University Press, p. 187. ISBN 0-521-20598-0.

- ^ Keller, Daniel; Price, Jennifer; Jackson, Caroline (2014). Neighbours and Successors of Rome: Traditions of Drinking glass Production and employ in Europe and the Heart East in the Later 1st Millennium AD. Oxbow Books. pp. 1–41. ISBN978-ane-78297-398-0.

- ^ Tutag, Nola Huse; Hamilton, Lucy (1987). Discovering Stained Drinking glass in Detroit . Wayne State University Press. pp. 11. ISBN978-0-8143-1875-1.

- ^ Packard, Robert T.; Korab, Balthazar; Chase, William Dudley (1980). Encyclopedia of American architecture . McGraw-Hill. pp. 268. ISBN978-0-07-048010-0.

- ^ a b One or more of the preceding sentences incorporates text from a publication now in the public domain:Chisholm, Hugh, ed. (1911). "Glass". Encyclopædia Britannica. Vol. 12 (11th ed.). Cambridge University Press. p. 86.

- ^ Freiman, Stephen (2007). Global Roadmap for Ceramic and Glass Technology. John Wiley & Sons. p. 705. ISBN978-0-470-10491-0.

- ^ "Low Glass". Archived from the original on 2 December 2022. Retrieved xix October 2007.

- ^ Gelfand, Lisa; Duncan, Chris (2011). Sustainable Renovation: Strategies for Commercial Building Systems and Envelope. John Wiley & Sons. p. 187. ISBN978-1-118-10217-6.

- ^ Lim, Henry Due west.; Honigsmann, Herbert; Militarist, John L.Yard. (2007). Photodermatology. CRC Press. p. 274. ISBN978-one-4200-1996-4.

- ^ Bach, Hans; Neuroth, Norbert (2012). The Properties of Optical Glass. Springer. p. 267. ISBN978-3-642-57769-seven.

- ^ McLean, Ian Due south. (2008). Electronic Imaging in Astronomy: Detectors and Instrumentation. Springer Science & Business Media. p. 78. ISBN978-3-540-76582-0.

- ^ a b c "Glass Applications – Glass Alliance Europe". Glassallianceeurope.eu. Retrieved 1 March 2022.

- ^ Enteria, Napoleon; Akbarzadeh, Aliakbar (2013). Solar Energy Sciences and Engineering Applications. CRC Press. p. 122. ISBN978-0-203-76205-nine.

- ^ "Gorilla Glass maker unveils ultra-thin and flexible Willow Glass". Physics News. Archived from the original on vi Nov 2022. Retrieved 1 November 2022.

- ^ "Xensation". Schott. Archived from the original on iii November 2022. Retrieved 1 November 2022.

- ^ Fingas, Jon (19 July 2022). "Gorilla Drinking glass half-dozen gives phones a amend shot at surviving multiple drops". Engadget.

- ^ a b c d Bach, Hans; Neuroth, Norbert (2012). The Backdrop of Optical Glass. Springer. pp. one–11. ISBN978-iii-642-57769-vii.

- ^ White, Mary Anne (2011). Physical Backdrop of Materials, Second Edition. CRC Printing. p. 70. ISBN978-one-4398-9532-0.

- ^ Carter, C. Barry; Norton, Grand. Grant (2007). Ceramic Materials: Science and Engineering. Springer Science & Business Media. p. 583. ISBN978-0-387-46271-iv.

- ^ Mysen, Bjorn O.; Richet, Pascal (2005). Silicate Glasses and Melts: Backdrop and Structure. Elsevier. p. ten.

- ^ a b c d e "Industrial drinking glass – Properties of glass". Encyclopedia Britannica.

- ^ Mattox, D.M. (2014). Handbook of Physical Vapor Deposition (PVD) Processing. Cambridge University Press. p. 60. ISBN978-0-08-094658-0.

- ^ Zarzycki, Jerzy (1991). Glasses and the Vitreous State. Cambridge University Press. p. 361. ISBN978-0-521-35582-7.

- ^ Thomas, Alfred; Jund, Michael (2013). Collision Repair and Refinishing: A Foundation Course for Technicians. p. 365. ISBN978-1-133-60187-6.

- ^ a b Gardner, Irvine Clifton; Hahner, Clarence H. (1949). Inquiry and Development in Applied Optics and Optical Drinking glass at the National Bureau of Standards: A Review and Bibliography. U.S. Regime Printing Function. p. 13. ISBN9780598682413.

- ^ Dudeja, Puja; Gupta, Rajul G.; Minhas, Amarjeet Singh (2016). Food Safety in the 21st Century: Public Health Perspective. Bookish Press. p. 550. ISBN978-0-12-801846-0.

- ^ Bengisu, Thou. (2013). Technology Ceramics. Springer Science & Business Media. p. 360. ISBN978-3-662-04350-nine.

- ^ Batchelor, Andrew W.; Loh, Nee Lam; Chandrasekaran, Margam (2011). Materials Degradation and Its Control by Surface Engineering. Earth Scientific. p. 141. ISBN978-i-908978-14-1.

- ^ a b c d Chawla, Sohan L. (1993). Materials Option for Corrosion Command. ASM International. pp. 327–328. ISBN978-1-61503-728-5.

- ^ Shaye Tempest (2004). "Density of Drinking glass". The Physics Factbook: An encyclopedia of scientific essays. Wikidata Q87511351.

- ^ "Glass Strength". www.pilkington.com. Archived from the original on 26 July 2022. Retrieved 24 November 2022.

- ^ Kenneth Chang (29 July 2008). "The Nature of Glass Remains Anything but Articulate". The New York Times. Archived from the original on 24 April 2009. Retrieved 29 July 2008.

- ^ a b c "Mining the ocean sand". Seafriends. eight Feb 1994. Archived from the original on 29 February 2022. Retrieved 15 May 2022.

- ^ a b c d e f "Glass – Chemistry Encyclopedia". Archived from the original on ii April 2022. Retrieved 1 April 2022.

- ^ a b B.H.W.S. de Jong, "Drinking glass"; in "Ullmann's Encyclopedia of Industrial Chemistry"; fifth edition, vol. A12, VCH Publishers, Weinheim, Germany, 1989, ISBN 978-3-527-20112-9, pp. 365–432.

- ^ a b Spence, William P.; Kultermann, Eva (2016). Construction Materials, Methods and Techniques. Cengage Learning. pp. 510–526. ISBN978-1-305-08627-two.

- ^ "Properties of PYREX®, PYREXPLUS® and Low Actinic PYREX Code 7740 Glasses" (PDF). Corning, Inc. Archived (PDF) from the original on 13 January 2022. Retrieved 15 May 2022.

- ^ "AR-GLAS® Technical Data" (PDF). Schott, Inc. Archived (PDF) from the original on 12 June 2022.

- ^ Shelby, J.East. (2017). Introduction to Glass Science and Technology. Royal Gild of Chemistry. p. 125. ISBN978-0-85404-639-3.

- ^ Schwartz, Mel (2002). Encyclopedia of Materials, Parts and Finishes (Second ed.). CRC Printing. p. 352. ISBN978-ane-4200-1716-viii.

- ^ Shackelford, James F.; Doremus, Robert H. (12 April 2008). Ceramic and Glass Materials: Structure, Backdrop and Processing. Springer Science & Business Media. p. 158. ISBN978-0-387-73362-3.

- ^ Askeland, Donald R.; Fulay, Pradeep P. (2008). Essentials of Materials Scientific discipline & Engineering. Cengage Learning. p. 485. ISBN978-0-495-24446-2.

- ^ "Glass Ingredients – What is Drinking glass Fabricated Of?". www.historyofglass.com. Archived from the original on 23 Apr 2022. Retrieved 23 April 2022.

- ^ Pfaender, Heinz G. (1996). Schott guide to glass. Springer. pp. 135, 186. ISBN978-0-412-62060-vii. Archived from the original on 25 May 2022. Retrieved viii February 2022.

- ^ Doering, Robert; Nishi, Yoshio (2007). Handbook of semiconductor manufacturing technology. CRC Press. pp. 12–13. ISBN978-1-57444-675-3.

- ^ a b c Holand, Wolfram; Beall, George H. (2012). Glass Ceramic Engineering science. John Wiley & Sons. pp. ane–38. ISBN978-1-118-26592-5.

- ^ Richerson, David W. (1992). Modern ceramic engineering : backdrop, processing and use in design (second ed.). New York: Dekker. pp. 577–578. ISBN978-0-8247-8634-two.

- ^ a b Parkyn, Brian (2013). Glass Reinforced Plastics. Elsevier. pp. 3–41. ISBN978-1-4831-0298-6.

- ^ Mayer, Rayner M. (1993). Pattern with reinforced plastics. Springer. p. seven. ISBN978-0-85072-294-9.

- ^ a b "Properties of Matter Reading Selection: Perfect Teamwork". www.propertiesofmatter.si.edu. Archived from the original on 12 May 2022. Retrieved 25 April 2022.

- ^ a b "Fibreglass | glass". Encyclopedia Britannica.

- ^ Greer, A. Lindsay; Mathur, N (2005). "Materials science: Irresolute Confront of the Chameleon". Nature. 437 (7063): 1246–1247. Bibcode:2005Natur.437.1246G. doi:x.1038/4371246a. PMID 16251941. S2CID 6972351.

- ^ Rivera, V. A. Yard.; Manzani, Danilo (30 March 2022). Technological Advances in Tellurite Spectacles: Properties, Processing, and Applications. Springer. p. 214. ISBN978-3-319-53038-3.

- ^ Jiang, Xin; Lousteau, Joris; Richards, Baton; Jha, Animesh (1 September 2009). "Investigation on germanium oxide-based glasses for infrared optical fibre development". Optical Materials. 31 (11): 1701–1706. Bibcode:2009OptMa..31.1701J. doi:ten.1016/j.optmat.2009.04.011.

- ^ J. W. E. Drewitt; South. Jahn; L. Hennet (2019). "Configurational constraints on glass germination in the liquid calcium aluminate system". Journal of Statistical Mechanics: Theory and Experiment. 2019 (x): 104012. arXiv:1909.07645. Bibcode:2019JSMTE..10.4012D. doi:ten.1088/1742-5468/ab47fc. S2CID 202583753.

- ^ C. J. Benmore; J. G. R. Weber (2017). "Aerodynamic levitation, supercooled liquids and glass formation". Advances in Physics: Ten. ii (three): 717–736. Bibcode:2017AdPhX...two..717B. doi:10.1080/23746149.2017.1357498.

- ^ Davies, H. A.; Hull J. B. (1976). "The formation, structure and crystallization of non-crystalline nickel produced by splat-quenching". Periodical of Materials Science. xi (two): 707–717. Bibcode:1976JMatS..11..215D. doi:10.1007/BF00551430. S2CID 137403190.

- ^ Klement, Jr., West.; Willens, R.H.; Duwez, Pol (1960). "Non-crystalline Structure in Solidified Gilded-Silicon Alloys". Nature. 187 (4740): 869. Bibcode:1960Natur.187..869K. doi:10.1038/187869b0. S2CID 4203025.

- ^ Liebermann, H.; Graham, C. (1976). "Production of Amorphous Blend Ribbons and Effects of Apparatus Parameters on Ribbon Dimensions". IEEE Transactions on Magnetics. 12 (6): 921. Bibcode:1976ITM....12..921L. doi:ten.1109/TMAG.1976.1059201.

- ^ Ponnambalam, V.; Poon, Due south. Joseph; Shiflet, Gary J. (2004). "Fe-based majority metallic glasses with bore thickness larger than 1 centimeter". Journal of Materials Research. 19 (5): 1320. Bibcode:2004JMatR..19.1320P. doi:10.1557/JMR.2004.0176.

- ^ "Metallurgy Segmentation Publications". NIST Interagency Report 7127. Archived from the original on 16 September 2008.

- ^ Mendelev, M.I.; Schmalian, J.; Wang, C.Z.; Morris, J.R.; K.G. Ho (2006). "Interface Mobility and the Liquid-Glass Transition in a One-Component System". Physical Review B. 74 (x): 104206. Bibcode:2006PhRvB..74j4206M. doi:x.1103/PhysRevB.74.104206.

- ^ "A main research field: Polymer glasses". world wide web-ics.u-strasbg.fr. Archived from the original on 25 May 2022.

- ^ Carraher Jr., Charles E. (2012). Introduction to Polymer Chemistry. CRC Printing. p. 274. ISBN978-1-4665-5495-v.

- ^ Ruby, S.Fifty.; Pelah, I. (2013). "Crystals, Supercooled Liquids, and Spectacles in Frozen Aqueous Solutions". In Gruverman, Irwin J. (ed.). Mössbauer Outcome Methodology: Volume 6 Proceedings of the Sixth Symposium on Mössbauer Upshot Methodology New York City, Jan 25, 1970. Springer Science & Business Media. p. 21. ISBN978-i-4684-3159-9.

- ^ Levine, Harry; Slade, Louise (2013). H2o Relationships in Foods: Advances in the 1980s and Trends for the 1990s. Springer Science & Business Media. p. 226. ISBN978-1-4899-0664-9.

- ^ Dupuy J, Jal J, Prével B, Aouizerat-Elarby A, Chieux P, Dianoux AJ, Legrand J (October 1992). "Vibrational dynamics and structural relaxation in aqueous electrolyte solutions in the liquid, undercooled liquid and burnished states" (PDF). Journal de Physique Four. 2 (C2): C2-179–C2-184. Bibcode:1992JPhy4...2C.179D. doi:10.1051/jp4:1992225. S2CID 39468740. European Workshop on Glasses and Gels.

- ^ Hartel, Richard W.; Hartel, AnnaKate (2014). Candy Bites: The Scientific discipline of Sweets. Springer Scientific discipline & Business organisation Media. p. 38. ISBN978-ane-4614-9383-9.

- ^ Charbel Tengroth (2001). "Structure of Ca0.4K0.6(NO3)1.4 from the glass to the liquid land". Phys. Rev. B. 64 (22): 224207. Bibcode:2001PhRvB..64v4207T. doi:10.1103/PhysRevB.64.224207.

- ^ "Lithium-Ion Pioneer Introduces New Battery That'due south Three Times Better". Fortune. Archived from the original on 9 Apr 2022. Retrieved half dozen May 2022.

- ^ "PFG Glass". Pfg.co.za. Archived from the original on 6 November 2009. Retrieved 24 October 2009.

- ^ Code of Federal Regulations, Championship 40,: Protection of Surround, Role 60 (Sections sixty.1-end), Revised As of July ane, 2022. Government Press Office. Oct 2022. ISBN978-0-sixteen-088907-3.

- ^ Ball, Douglas J.; Norwood, Daniel L.; Stults, Cheryl L. M.; Nagao, Lee M. (24 January 2022). Leachables and Extractables Handbook: Safety Evaluation, Qualification, and All-time Practices Applied to Inhalation Drug Products. John Wiley & Sons. p. 552. ISBN978-0-470-17365-7.

- ^ Chisholm, Hugh, ed. (1911). . Encyclopædia Britannica. Vol. 12 (11th ed.). Cambridge University Press. pp. 87–105.

- ^ "windshields how they are made". autoglassguru. Retrieved nine February 2022.

- ^ Pantano, Carlo. "Glass Surface Treatments: Commercial Processes Used in Drinking glass Manufacture" (PDF).

- ^ a b "Glass melting, Pacific Northwest National Laboratory". Depts.washington.edu. Archived from the original on 5 May 2022. Retrieved 24 October 2009.

- ^ Fluegel, Alexander. "Drinking glass melting in the laboratory". Glassproperties.com. Archived from the original on 13 Feb 2009. Retrieved 24 Oct 2009.

- ^ a b c d e f Mukherjee, Swapna (2013). The Science of Clays: Applications in Manufacture, Applied science, and Environment. Springer Science & Business Media. p. 142. ISBN978-nine-4007-6683-9.

- ^ Walker, Perrin; Tarn, William H. (1990). CRC Handbook of Metallic Etchants. CRC press. p. 798. ISBN978-1-4398-2253-one.

- ^ a b Langhamer, Antonín (2003). The Legend of Maverick Glass: A Grand Years of Glassmaking in the Heart of Europe. Tigris. p. 273. ISBN978-8-0860-6211-2.

- ^ "three. Glass, Color and the Source of Cobalt". Internet Archaeology.

- ^ Chemic Fact Sheet – Chromium Archived 2022-08-xv at the Wayback Machine www.speclab.com.

- ^ David M Issitt. Substances Used in the Making of Coloured Glass 1st.glassman.com.

- ^ Shelby, James E. (2007). Introduction to Glass Science and Engineering. Royal Guild of Chemical science. p. 211. ISBN978-1-84755-116-0.

- ^ a b Nicholson, Paul T.; Shaw, Ian (2000). Ancient Egyptian Materials and Technology. Cambridge University Printing. p. 208. ISBN978-0-521-45257-1.

- ^ Weller, Bernhard; Unnewehr, Stefan; Tasche, Silke; Härth, Kristina (2012). Glass in Building: Principles, Applications, Examples. Walter de Gruyter. pp. 1–xix. ISBN978-iii-0346-1571-6.

- ^ a b "The rising of drinking glass buildings". Glass Times. ix January 2022. Retrieved 1 March 2022.

- ^ Patterson, Mic (2011). Structural Glass Facades and Enclosures. Jon Wiley & Sons. p. 29. ISBN978-0-470-93185-ane.

- ^ Hynes, Michael; Jonson, Bo (1997). "Lead, glass and the environment". Chemical Society Reviews. 26 (two): 145. doi:10.1039/CS9972600133.

- ^ "Cut glass | decorative arts". Encyclopedia Britannica.

- ^ "Loftier temperature drinking glass melt property database for process modeling"; Eds.: Thomas P. Seward Iii and Terese Vascott; The American Ceramic Guild, Westerville, Ohio, 2005, ISBN 1-57498-225-seven

- ^ "Why choose Glass?". FEVE.

- ^ Sun, P.; et, al. (2018). "Design and Fabrication of Glass-based Integrated Passive Devices". IEEE, 19th International Conference on Electronic Packaging Applied science (ICEPT): 59–63. doi:10.1109/ICEPT.2018.8480458. ISBN978-one-5386-6386-eight. S2CID 52935909.

- ^ Letz, 1000.; et, al. (2018). "Glass in Electronic Packaging and Integration: High Q Inductances for two.35 GHz Impedance Matching in 0.05 mm Thin Drinking glass Substrates". IEEE 68th Electronic Components and Technology Conference (ECTC): 1089–1096. doi:10.1109/ECTC.2018.00167. ISBN978-1-5386-4999-ii. S2CID 51972637.

- ^ Lundén, H.; et, al. (2004). "Novel glass welding technique for hermetic encapsulation". Proceedings of the 5th Electronics System-integration Technology Briefing (ESTC): ane–four. doi:10.1109/ESTC.2014.6962719. ISBN978-one-4799-4026-4. S2CID 9980556.

- ^ a b Zumdahl, Steven (2013). Lab Manual. Cengage Learning. pp. ix–15. ISBN978-1-285-69235-7.

- ^ "Science Under Glass". National Museum of American History. 29 July 2022.

- ^ Basudeb, Karmakar (2017). Functional Glasses and Glass-Ceramics: Processing, Properties and Applications. Butterworth-Heinemann. pp. 3–five. ISBN978-0-12-805207-v.

- ^ "Scientific Glassblowing | National Museum of American History". Americanhistory.si.edu. 17 Dec 2022. Retrieved 4 March 2022.

- ^ Tut'southward gem hints at space impact, BBC News, July 19, 2006.

- ^ The Earliest Cloisonné Enamels

- ^ Arwas, Victor (1996). The Art of Glass: Art Nouveau to Fine art Deco. pp. i–54. ISBN978-i-901092-00-4.

- ^ "A-Z of glass". Victoria and Albert Museum. Retrieved ix March 2022.

External links

- . Encyclopædia Britannica. Vol. 12 (11th ed.). 1911.

- The Story of Drinking glass Making in Canada from The Canadian Museum of Civilization.

- "How Your Drinking glass Ware Is Made" by George W. Flit, February 1951, Pop Scientific discipline.

- All About Glass from the Corning Museum of Drinking glass: a collection of articles, multimedia, and virtual books all about glass, including the Glass Dictionary.

- National Drinking glass Association—The largest trade association representing the flat (architectural), auto drinking glass, and window & door industries

Source: https://en.wikipedia.org/wiki/Glass

Posted by: hullwilet1954.blogspot.com

0 Response to "What Is The Regular Price To Repair Both The Front And Back Glass Of A Phone"

Post a Comment